Gate valves are a fundamental component in piping and fluid control systems. Designed primarily to start or stop fluid flow, gate valves operate by lifting a gate (a wedge or disc) out of the path of the fluid. They are favoured for applications that require full-bore flow or tight shut-off and are commonly used across water supply, wastewater treatment, chemical processing, oil & gas, power generation and many other industries.

For contractors, traders and bulk buyers, purchasing gate valves from wholesalers is often the most economical route — delivering wide size ranges, material options, and competitive pricing for large orders.

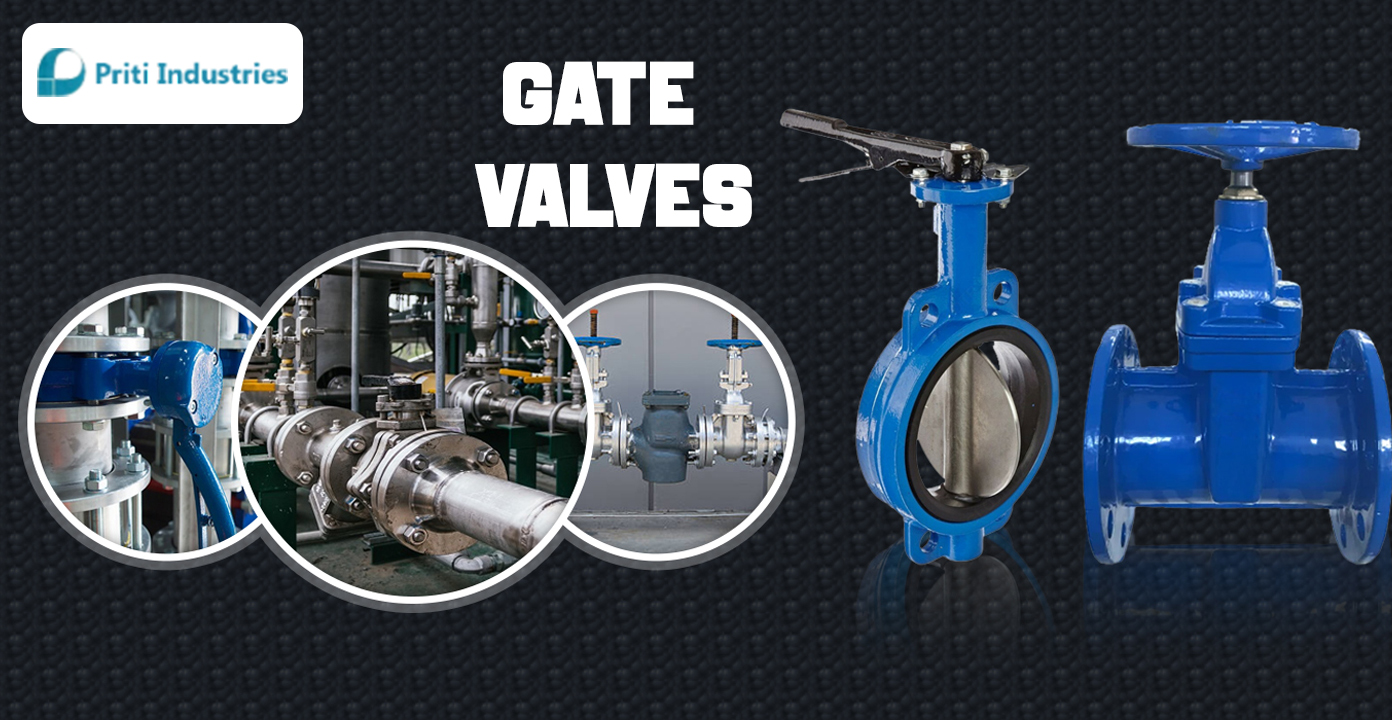

M/S Priti Industries is a well-reputed company in the industry for manufacturing, exporting, and supplying premium quality products. The company has been manufacturing since 2012 and caters to both domestic and international markets. Their portfolio includes a wide range of fittings, valves and allied components suitable for industrial, commercial and infrastructure applications.

| Business Type | Manufacturer, Exporter, Retailer |

|---|---|

| Year of ESTD | 2012 |

| Ownership Type | Others |

| No of Employees | Less than 10 People |

| Major Markets Cover | India, Abroad |

| GST No | 27BDZPG1623G1ZE |

Gate valves are available in multiple designs. Each type is optimized for different operating conditions — pressure, temperature, media type, installation location, and maintenance access.

A one-piece wedge provides robustness and reliability. Solid wedge gates are best for clean fluids and applications where a simple, durable valve is required.

Flexible wedge valves have a wedge that flexes to maintain sealing under variable temperatures or minor seat misalignment. They reduce the risk of jamming due to thermal expansion.

With a two-piece split wedge, this design is self-aligning and helps reduce stress on the seating surfaces. Frequently used in medium-duty pipelines and non-condensing gas applications.

The stem visibly rises when the valve is opened, providing a clear indication of valve position. Commonly used for outdoor installations and waterworks where position indication and visual confirmation are helpful.

The stem does not move up or down as the gate moves; instead the gate moves internally. This compact design is suited to confined or underground installations.

Parallel slide gate valves use parallel seating surfaces and are commonly used in boiler feed applications and systems where tight shut-off and long-term durability under thermal cycling are needed.

Knife gate valves have a sharp-edged gate designed to cut through slurry, sludge or fibrous materials. They are ideal for wastewater treatment, pulp & paper and other heavy slurry applications.

The material choice affects valve life, corrosion resistance and suitability for different fluids. Wholesalers and manufacturers provide gates in a variety of materials to match operating requirements.

Wholesale prices vary based on size (nominal diameter), material, pressure rating (PN / Class), end connection (flanged, threaded, butt-weld) and brand customization. The following table provides a general price band commonly found in India for standard designs:

| Valve Type / Material | Typical Wholesale Price Range (per piece) | Typical Applications |

|---|---|---|

| Cast Iron Gate Valve | Rs 600 – Rs 1,800 | Municipal water, low-pressure distribution |

| Ductile Iron Gate Valve | Rs 1,200 – Rs 3,000 | Higher strength water lines, utilities |

| Bronze Gate Valve | Rs 2,000 – Rs 5,000 | Marine, chemical, potable water |

| Stainless Steel Gate Valve | Rs 2,500 – Rs 7,500 | Corrosive chemicals, food & pharma, refineries |

| Forged Steel Gate Valve | Rs 4,000 – Rs 10,000 | High-pressure oil & gas, power plants |

| Knife Gate Valve | Rs 5,000 – Rs 15,000 | Slurry, wastewater, pulp & paper |

| PVC / UPVC Gate Valve | Rs 300 – Rs 1,000 | Low pressure water supply, irrigation |

Note: Prices shown are indicative wholesale ranges to help buyers estimate budget. Actual quotations depend on exact specifications, order quantities, testing or certification requirements, surface treatment and delivery location.

Gate valves are used across many sectors due to their simple operation and effective shut-off capability:

Buying from wholesalers and traders provides benefits that suit bulk buyers, contractors and exporting businesses:

Selecting the appropriate gate valve requires attention to the operating conditions and project specifications. Use the checklist below when evaluating options:

Is the valve for water, oil, gas, slurry or chemical services? Media type determines material and sealing choices.

Choose cast iron, ductile iron, bronze, stainless steel, forged steel or PVC based on corrosion, pressure and temperature needs.

Match the valve's rated pressure class (e.g., PN or ANSI class) and temperature limits to your system.

Decide between flanged, threaded, socket-weld, butt-weld or wafer-style connections per piping specs.

Rising stem offers visual position indication; non-rising stem is compact for tight spaces. Consider actuator or gearbox options for large valves.

Check availability of spare seats, glands and packing; prefer designs that allow easier onsite maintenance.

M/S Priti Industries and similar Indian manufacturers supply valves to markets abroad. Common export destinations include Middle Eastern countries (for oil & gas and infrastructure projects), African markets (water and utilities), South East Asia (industrial projects) and occasionally specialized supplies to Europe and the Americas when standards and certifications match.

Ensure valves conform to recognized standards where applicable: API, ANSI, BS, IS and ISO. For critical applications, request test certificates, material traceability and inspection reports from the manufacturer or trader.

Gate valves remain a cost-effective and reliable choice for on/off control in many industries. By selecting the right type and material and sourcing from reputable wholesalers such as M/S Priti Industries, buyers can achieve a balance of performance, longevity and cost-efficiency. Always obtain detailed technical datasheets and final quotations to ensure the supplied valve precisely matches your system requirements.

For specifications, bulk pricing or export enquiries, contact the manufacturer or your preferred trader. Provide details such as valve size (DN), pressure class (PN/ANSI), material, end connection and estimated quantity to receive an accurate quotation and lead time.