Glycerin filled pressure gauges are a popular choice across industrial and commercial applications where vibration, pulsation or aggressive service conditions can harm dry gauges. The glycerin damping reduces needle flutter, improves readability and extends the life of the mechanism. This guide explains the main types of glycerin filled pressure gauges, expected price ranges, where to source them from wholesalers and traders, and practical tips on selection and maintenance.

M/S Priti Industries is a well-reputed company in the industry for manufacturing, exporting, and supplying premium quality products. Their product range includes Tube Fittings, Pipe Fittings, Flanges, QRC & Camlock Coupling, Needle Valves, Knife Gate Valve, Valves, Nut Bolt, Pipe Clamp and Pressure Gauge. The company focuses on durable, standards-compliant components for process, fluid handling and mechanical systems.

| Business Type | Manufacturer, Exporter, Retailer |

|---|---|

| Year of ESTD | 2012 |

| Ownership Type | Others |

| No of Employees | Less than 10 People |

| Major Markets Cover | India, Abroad |

| GST No | 27BDZPG1623G1ZE |

| Category | Details |

|---|---|

| Quality Standards | Conforms to ISO 9001 manufacturing standards, calibrated as per EN 837 / ASME B40.100, available with traceable calibration certificates on request. |

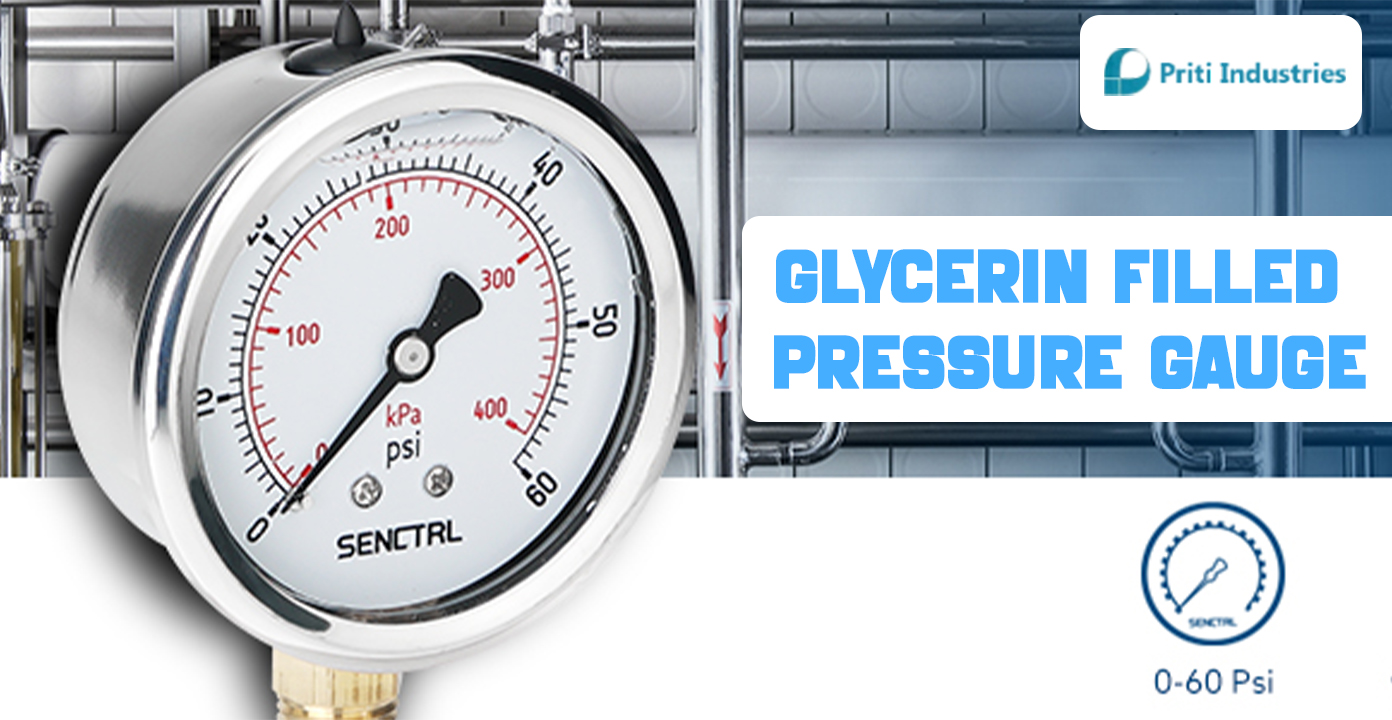

| Features | Shock-resistant due to glycerin filling, corrosion-resistant case options, dual scale display, high readability, extended service life, available in multiple connection sizes and dial diameters. |

| Uses | Widely used in hydraulic systems, water treatment plants, compressors, refrigeration systems, HVAC equipment, chemical processing, and industrial machinery subject to vibration. |

A glycerin filled pressure gauge contains a liquid (typically glycerin or a glycerin-based mixture) inside the case. The lubricant dampens internal movement, stabilises the pointer under vibration/pulsation and lubricates the movement. These gauges are commonly used in compressors, hydraulic systems, refrigeration, water treatment and other process equipment where mechanical shock or pulsation is present.

Classic Bourdon tube based analog gauge with a glycerin-filled case. Suitable for general industrial use, available in different dial sizes (40 mm, 63 mm, 100 mm, 150 mm) and pressure ranges (vacuum to high pressure depending on model).

Designed for corrosive environments and outdoor use. The stainless steel case plus glycerin fill protects internal parts and ensures longer life in aggressive or wet environments.

Connection orientation matters for panel mounting or direct pipe mounting. Bottom connection gauges mount directly to pipelines; back connection models are designed for panel installation.

Gauges showing two scales (e.g., bar and psi) or compound gauges capable of indicating vacuum and pressure. Useful where operators require multiple units on the same instrument.

Safety pattern filled gauges include blow-out back and other safety measures to protect operators in case of internal failure—recommended where there is a risk of overpressure or brittle fluids.

Manufacturers like M/S Priti Industries can provide custom dials, mounting arrangements or special ranges to suit OEM needs or bulk orders for industrial panels.

Prices vary by brand, material, accuracy and quantity. The figures below are indicative wholesale ranges to help budget planning (prices expressed as approximate ranges per unit):

Note: For exact prices, contact wholesalers or M/S Priti Industries directly. Bulk orders substantially reduce unit cost — always request a formal quotation with lead time, packing and shipping costs included.